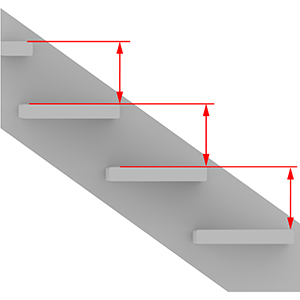

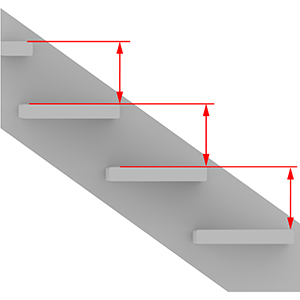

Keep an eye on the parameter control bar above the staircase diagram; if the values are green, the staircase is comfortable. In special situations, use the recommendations provided by our system to make decisions.

Headroom

mm

Value >=

mm

Run

mm

Value >=

-

mm

Rise

mm

Value >=

-

mm

Effective width

mm

Value >=

mm

Stair formula

mm

Value >=

-

mm

SEE THE STAIRS PICTURE

English

English Sweden

Sweden Finland

Finland Norway

Norway English

English